Made In The USA

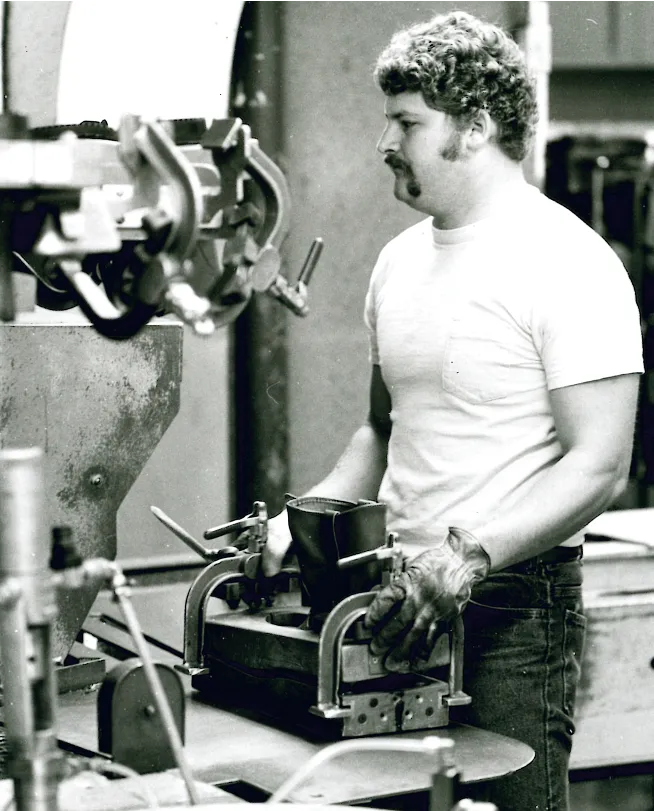

Built start to finish in the USA, using American labor and over 95% USA-made materials. No shortcuts, just boots built with pride.

Made In The USA With Imported Parts

American workers handle every step — from stitching to final assembly — but some of the materials are carefully selected, premium, globally-sourced components.

Made In The USA With Imported Components

We cut S.B. Foot Leather into components here in the U.S., then send them out for stitching. Once they’re back, we finish the job here in our U.S. factories.

Assembled In The USA With Imported Components

S.B. Foot Leather, or other locally sourced leather, is stitched overseas, then we bring it all together in our U.S. factories. Final assembly, quality control and packaging all happen in the U.S.